Nicholas Newman is an Oxford based journalist, blogger, editor, and consultant that covers a range of topics in the global energy, technology, and transport sectors as they apply to extraction, markets, regulation, fiscal and policy sectors.

Getac Select

A combination of rugged computing devices, software, accessories and professional services in a purposeful range of specifically tailored solutions.

Getac Video Solutions

Video capture, evidence management, rugged hardware and robust software solutions for law enforcement and other industries.

Defense

Mission-critical COTS computing that delivers high powered processing and reliability in operational environments

Public Safety

Law Enforcement, EMS, Fire & Rescue applications

Utilities

Smart Meter Reading and Installation, On-site Safety, Utility Asset Management, Workforce Management for Utilities, Mobile GIS, Surveying and Mapping

Transportation & Logistics

Railroad Management, Airport Management, Port Management, Long-haul Delivery Fleet Management, Warehouse Materials Handling

Industrial Manufacturing

Industrial Programming and Robotic Control, Facility management, Compliance and Inspections, Workforce Management, Inventory and Warehouse Management, Factory Automation and Plant Monitoring, EAM and CMMS Solutions.

Automotive

Optimized Rugged Mobile Solutions to drive a smarter approach throughout the automotive value-chain.

Natural Resources

Mining, Forestry and Construction applications

Oil & Gas

Remote Support, Asset Management, Field Data Analysis, Workplace Safety

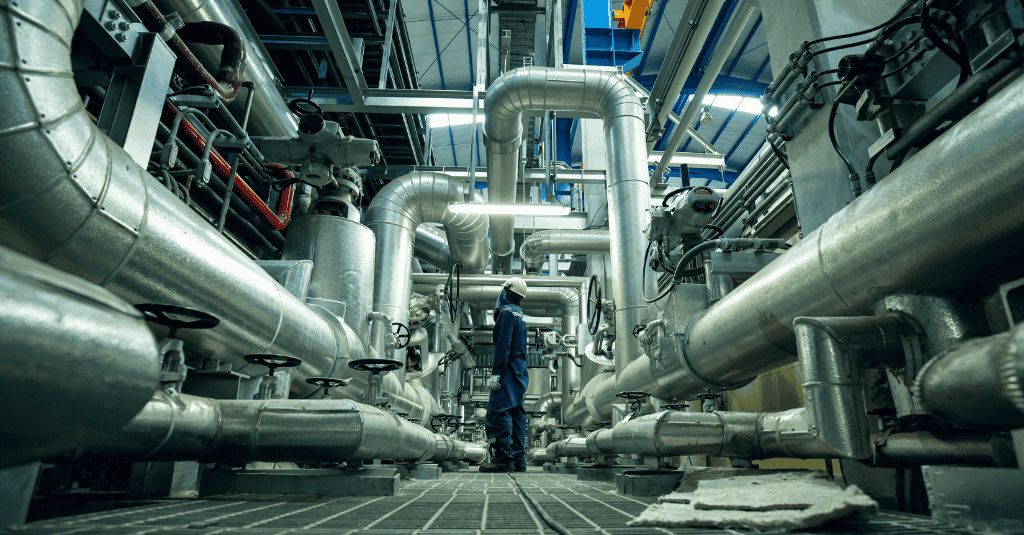

Keeping track of assets and equipment spread over multiple worksites and often remote locations is a constant challenge. For an oil company, centralizing information and data on fixed and mobile assets is invaluable. Two complementary technologies, namely Geographical Positioning Software (GPS) and Geographical Information Systems (GIS) software, are the industry’s tools of choice. GPS is designed to identify, manage, and allocate mobile assets throughout the value and logistic chain. GIS is designed for land assets. GIS can store, retrieve, manage, display, and analyze geographic and spatial data. Organizations in the industry use this technology for good placement, bloc evaluations, and land management.

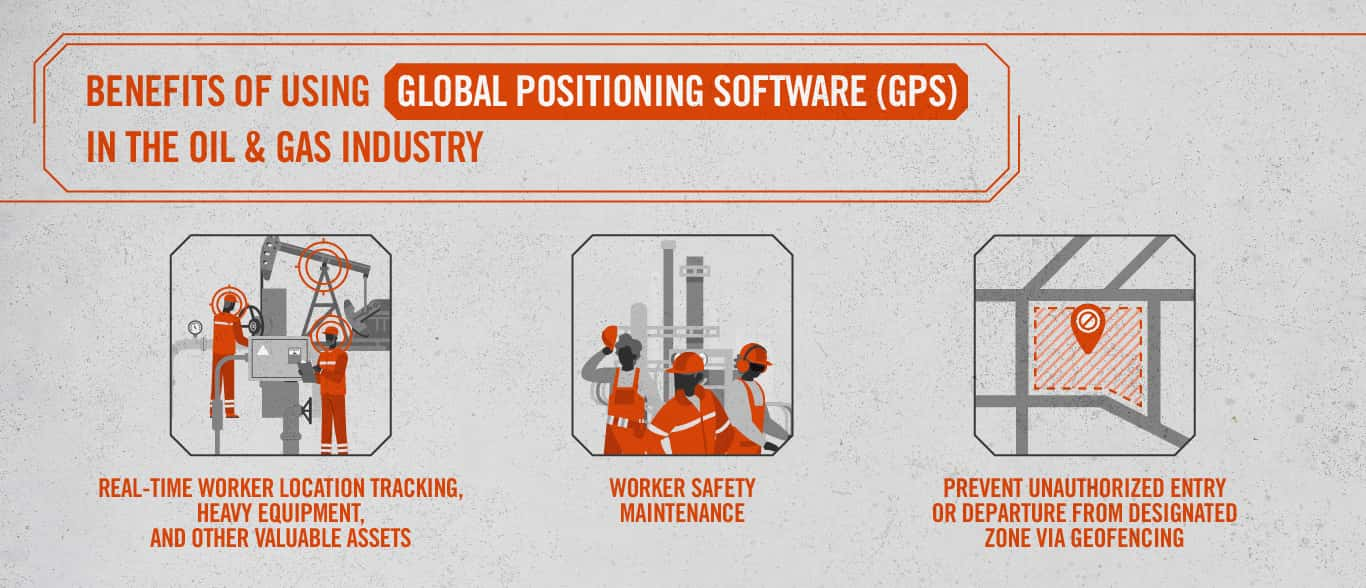

GPS tracking technology is ideal for monitoring the daily whereabouts of expensive heavy equipment. Workers can also use its tracking movement between sites. For instance, workers using GPS trackers monitor assets across Alaska's harsh and remote North Slope. Several commercial GPS devices are ideally suited to provide asset management solutions for the oil industry. For example, the Oil & Gas GPS tracking system from Trackimo provides oil companies with tools to track the location of crews, heavy equipment, and other valuable assets.

Using a GPS tracking solution helps energy companies maintain staff safety. For example, Nano Tracker detects the wearer’s location via GPS. Moreover, workers can activate its integral Panic Button in an emergency. Geofencing creates an alert when the wearer leaves a predetermined geographic area in a similar vein. If the accelerometer fails to detect movement for a certain period, the device automatically sends out an emergency call.

Real-time tracking enables managers to locate an asset, its status, and a historical record of its movement. Data obtained from these practices can help improve efficiency. Pipelines are the lifeblood of the oil and gas industry, and just like arteries and veins, they need to be clear to run smoothly. Pipeline Inspection Gauges (PIGs) are devices that run inside pipelines. These tools take readings and pictures to detect anomalies or signs of corrosion, leading to leaks or bursts. Technicians can align PIG readings with an exact location by tracking devices along pipelines and GPS-synch time and location technology. This information helps them improve the accuracy of PIG readings and reduce the time and costs associated with doing PIG runs.

GPS also provides real-time updates on the location of specific vehicles or vessels worldwide. In addition, organizations can fit heavy equipment with GPS tracking devices to monitor temperature and fuel level changes. This allows managers to see if workers use the equipment safely and efficiently.

Geo-fencing and notifications use GPS to create spatial virtual fences, which can be any shape or size, to prevent entry by company vehicles. A case in point is Geo-fencing to prevent a high-sided vehicle from driving under a low bridge. Likewise, this GPS software can record and track personnel entering and leaving a geofenced zone.

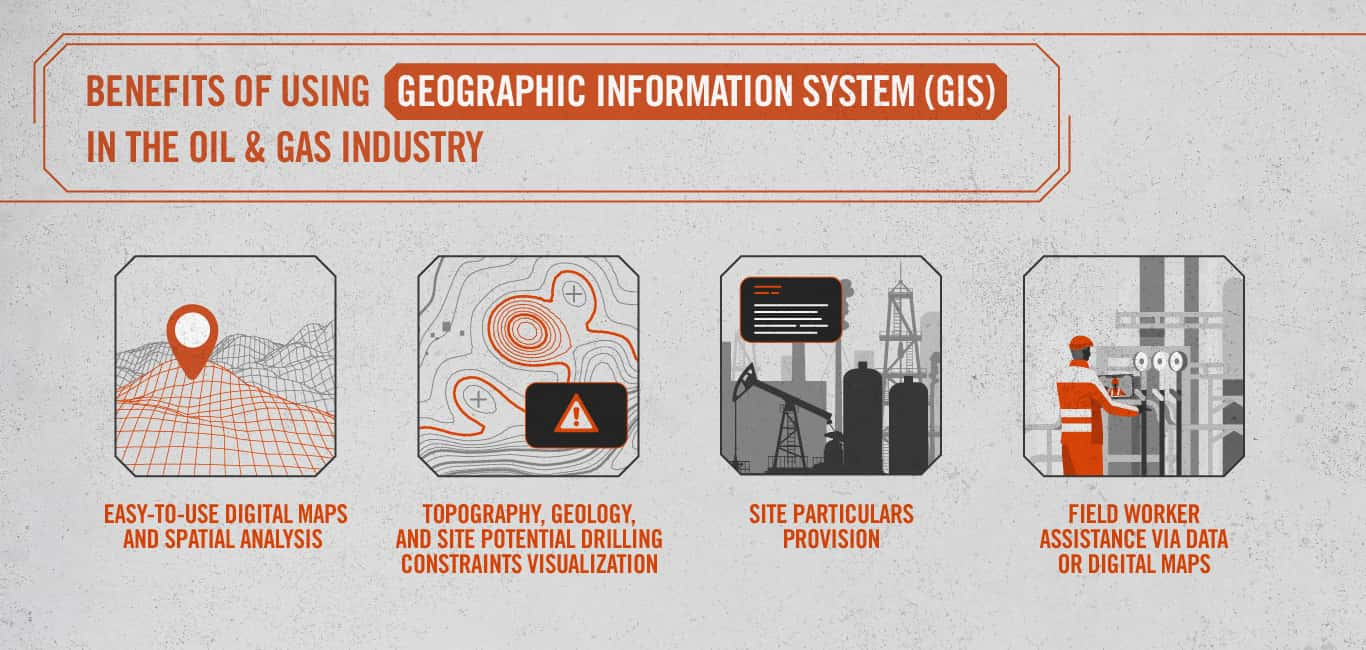

GIS helps companies manage their land assets by providing easy-to-use digital maps and spatial analysis. Throughout the extraction process, management and crew can use this technology in the field. GIS lets decision-makers see the topography, geology, and potential drilling constraints on a site in 3Dimensions. Moreover, with GIS mapping, managers can superimpose high-resolution imagery onto existing site maps to help determine project selections and surveys. Once managers select the site, they can visualize the oil well planning process in 3D. GIS also enables users to comprehend large volumes of geographic data visually. This practice complies with local laws and regulations at a particular location. GIS software has been especially valuable in shale plays to determine well-pad patterns. Spatial analytics help determine the most effective drilling configuration.

GIS software can provide particulars of a site. This includes the landowner’s name, planning restrictions, or lease expiration dates regarding land management data. In evaluating a possible bid at auction, GIS software can incorporate tailored information to feed into whether or not to bid for an oil bloc license. It is thought that oil majors employed GIS software to guide their response to Brazil’s November 2019 offshore oil and gas license auction.

Energy companies use aerial drones equipped with GIS software to obtain high-quality images of their sites in the field. These images track subsidence, a significant risk in high-intensity drilling areas like Texas. As for planning pipeline routes, GIS helps owners juggle with stakeholders, including landowners, planning authorities, state regulators, and construction firms. Similarly, GIS tools are invaluable in helping companies avoid sinkholes, earthquake-prone areas, or even national parks. For example, the Atlantic Coast gas pipeline route in North Carolina and Virginia had to be changed to protect the wildlife in the Great Dismal Swamp.

Finally, GIS can also help employees on the ground. These benefits include repairing a drill or compressor by providing data to answer a particular need or producing digital maps. The digital maps delivered by web-based GIS applications require little or no staff training before use. They display all relevant data in a single interface. Workers can monitor this information on a mobile phone or tablet computer with 3D goggles.

These complementary technologies provide oil companies with the tools to account for their fixed and mobile assets.

Nicholas Newman is an Oxford based journalist, blogger, editor, and consultant that covers a range of topics in the global energy, technology, and transport sectors as they apply to extraction, markets, regulation, fiscal and policy sectors.