ATEX & IECEX

Learn about ATEX and IECEx, the different hazardous environments in which products with these certifications can be used, and how Getac can help you.

WHAT DOES ATEX MEAN?

ATEX is an abbreviation from the French, ATmosphère EXplosible (or explosive atmospheres, translated into English). This a term is used in the EU ATEX Directive 94/9/EC (now replaced by ATEX Directive 2014/34/EU), a code meant to regulates devices used in explosive atmospheres. Generally, “ATEX” is used to refer to those ATEX certifications/standards and a product’s suitability for being used in hazardous environments

WHAT DOES ATEX CERTIFIED MEAN?

ATEX certification is given to equipment that has gone through rigorous testing outlined by European Union directives. Products that are ATEX compliant have been proved safe to use in specific environments with explosive atmospheres, according to the zone/s they are certified to be used in.

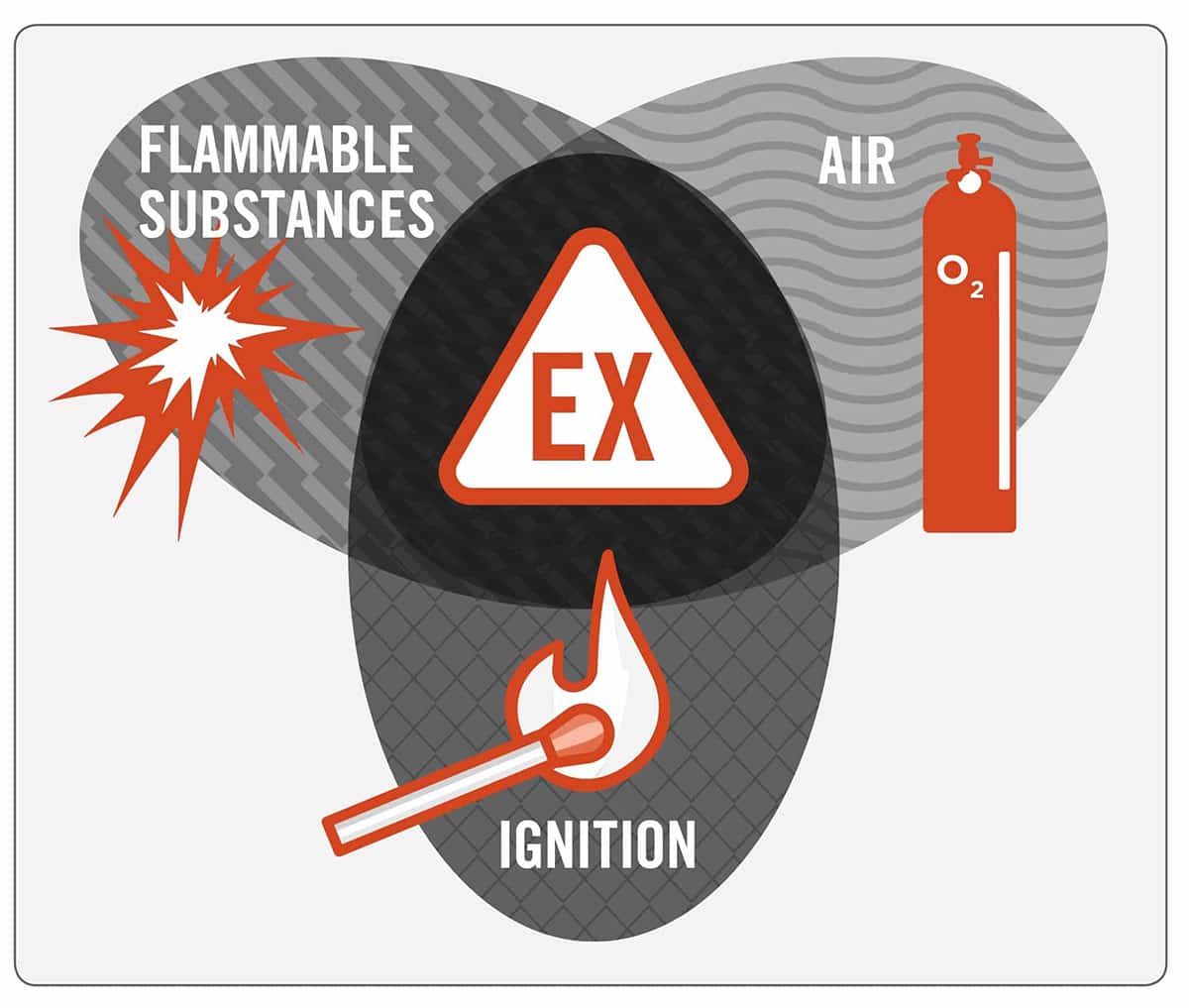

The European Union has mandated that ATEX compliance is necessary wherever a potentially explosive atmosphere exists in order to keep workers safe. These atmospheres are characterized by possessing three things.

- • air

- • an ignition source

- • one of the following three substances:

- • flammable gases

- • mists or vapor

- • combustible dust

Products that have received ATEX certification will have the official “Ex” badge, indicating they are safe in explosive atmospheres.

Non-ATEX/IECEx safe computing devices used in hazardous areas could be an ignition source, so it is critical that ATEX/IECEx certified computing devices are used in those areas. If they are not, the situation immediately poses great risk to workers’ safety. That’s why we’ve built rugged computing devices that are ATEX/IECEx certified.

WHAT DOES IECEX CERTIFIED MEAN?

Similar to ATEX certification, IECEx certification is given to products that have been thoroughly tested and proven to work safely in environments with explosive atmospheres.

IECEx certification is an internationally accepted method that demonstrates compliance with IEC (International Electrotechnical Commission) standards. IEC standards and assessments are recognized internationally as a benchmark for fields of electrotechnology.

ATEX CERTIFICATION VS. IECEX CERTIFICATION

Equipment with either or both ATEX and IECEx certifications have met stringent requirements and are tested and certified to work in explosive environments. The main difference comes down to geography. ATEX certification is well-known, but it is specific to the European Union, while IECEx certification is accepted in other regions.

ATEX VS. IECEX CLASSIFICATION

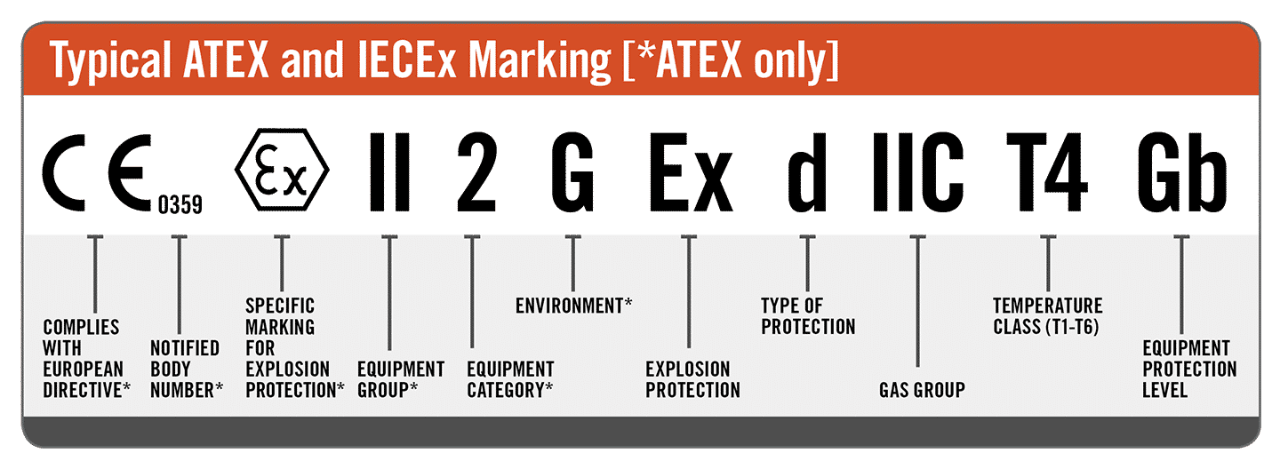

ATEX and IECEx products are classified and grouped into various categories as well as further subdivided into Zones, Groups, Protection Types, and Equipment Protection Levels (EPLs).

Below is a sample marking for ATEX products. Certain classifications are only featured on ATEX equipment and not on IECEx products.

ATEX ZONES AND EQUIPMENT CATEGORIES

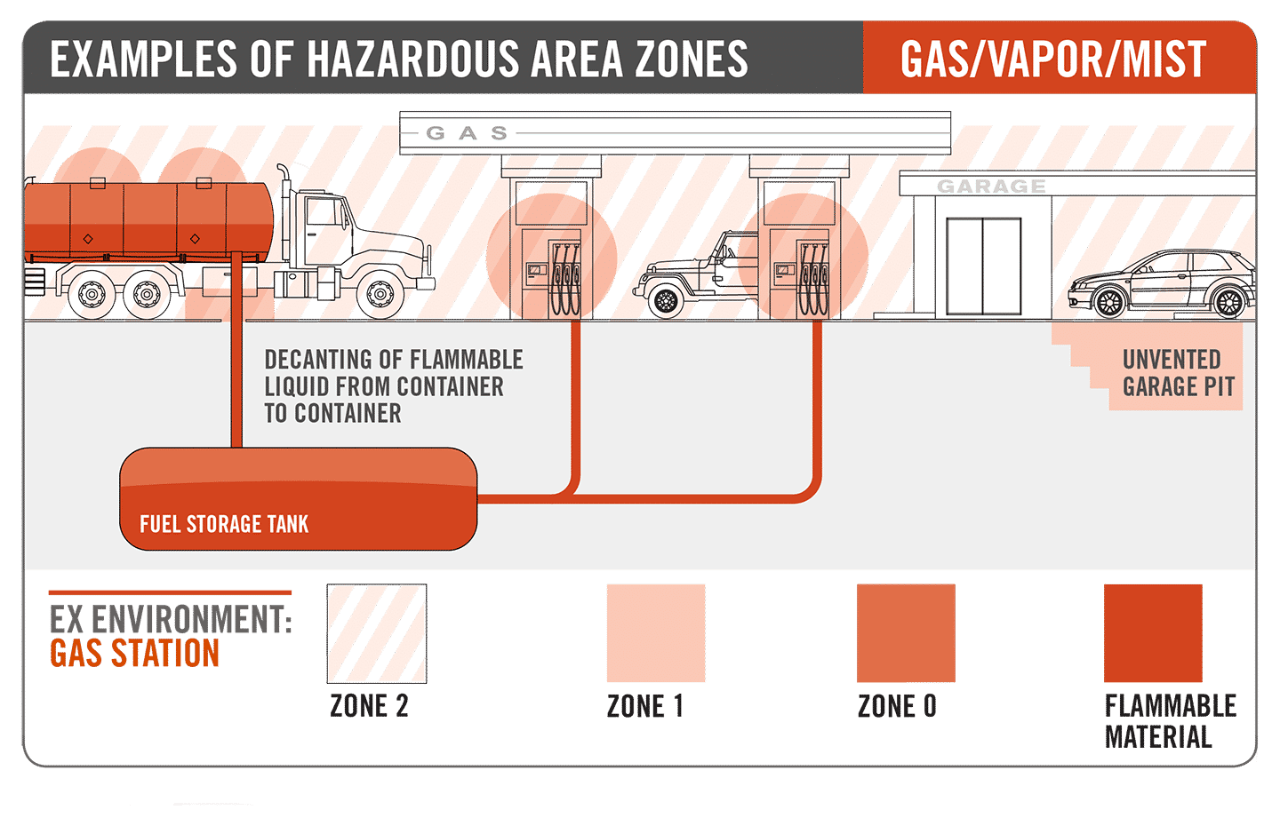

Explosive atmospheres are found in different environments, such as mines, factories, oil and gas rigs, and flour and wood mills, to name a few. Hazardous area zones have been defined according to the frequency of the presence of explosive materials in specific areas. Each zone has specific categories of equipment allowed.

Zone 0, 1, 2 – These are zones specifically for atmospheres with hazardous gases, vapors, and mist.

- Zone 0 – Explosive mixtures are present continuously. Category 1 equipment required.

- Zone 1 – Explosive mixtures are present intermittently. Category 2 or 1 equipment required.

- Zone 2 – Explosive mixtures are present abnormally or infrequently. Category 3, 2, or 1 equipment required.

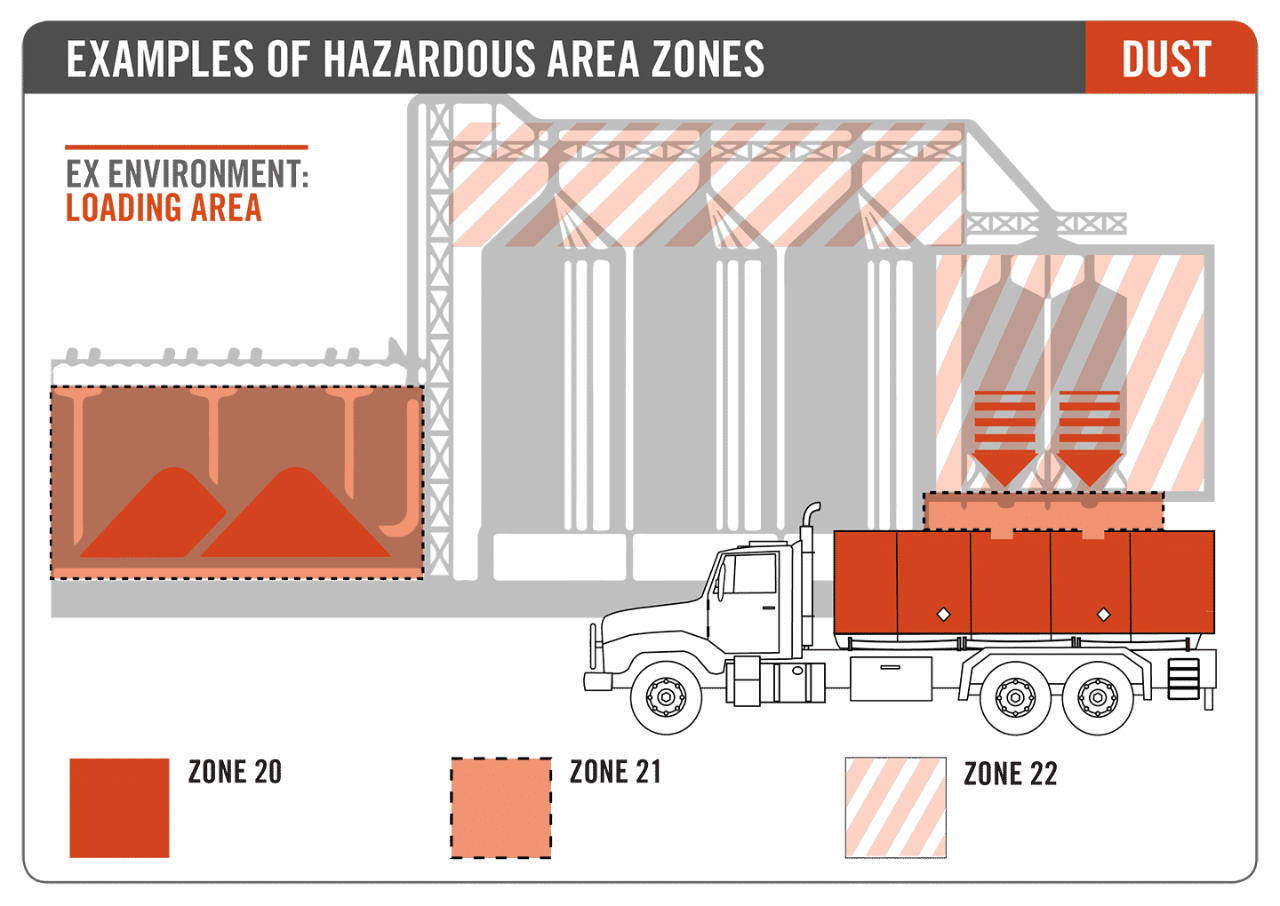

Zone 20, 21, 22 – These are zones for areas in which dust clouds are or might be present.

- Zone 20 – Explosive mixtures are present in the air continuously. Category 1 equipment required.

- Zone 21 – Explosive mixtures are present in the air intermittently. Category 2 or 1 equipment needed.

- Zone 22 – Explosive mixtures are present abnormally or infrequently in the air. Category 3, 2, or 1 equipment required.

POTENTIAL APPLICATIONS FOR ATEX/IECEX CERTIFIED COMPUTING DEVICES

Working with hazardous materials requires vigilant explosion protection in all industries where explosive atmospheres may be present. Getac offers ATEX/IECEx certified tablets, helping professionals stay focused and safe while doing their job. Solutions built on these devices can be suitable for different uses, some of which include:

- factories where explosive atmospheres may be present, including food production, pharmaceuticals, painting, manufacturing, etc.

- processing plants or refineries where natural resources including oil and gas, or chemicals may be processed

- mines where explosive atmospheres containing hazardous gases or other materials may be present

- in the field whether working in pharmaceuticals, agriculture, chemical, manufacturing, mining, oil and gas, or other areas.

GETAC ATEX/IECEX CERTIFIED COMPUTING RUGGED TABLETS

Working in hazardous areas requires equipment rugged enough to withstand extreme situations while simultaneously minimizing risks to the safety of your team. Getac is proud to offer a range of tablets that meet the stringent regulations to work in explosive environments and is ATEX and IECEx (for details please check the specific product's spec sheet) certified.