Rugged Device Certifications Explained: ATEX, IECEx, Hazardous Locations

Discover the differences between Hazardous Locations, ATEX, and IECEx certifications for device safety in hazardous environments. Learn how Getac ensures compliance.

Last Updated: November 2025

At-a-Glance: Comparing ANSI/UL, ATEX, and lECEX Certifications

| Certification | Region/Authority | Applicable Standards | Classification System | Key Use Cases | More Info |

|---|---|---|---|---|---|

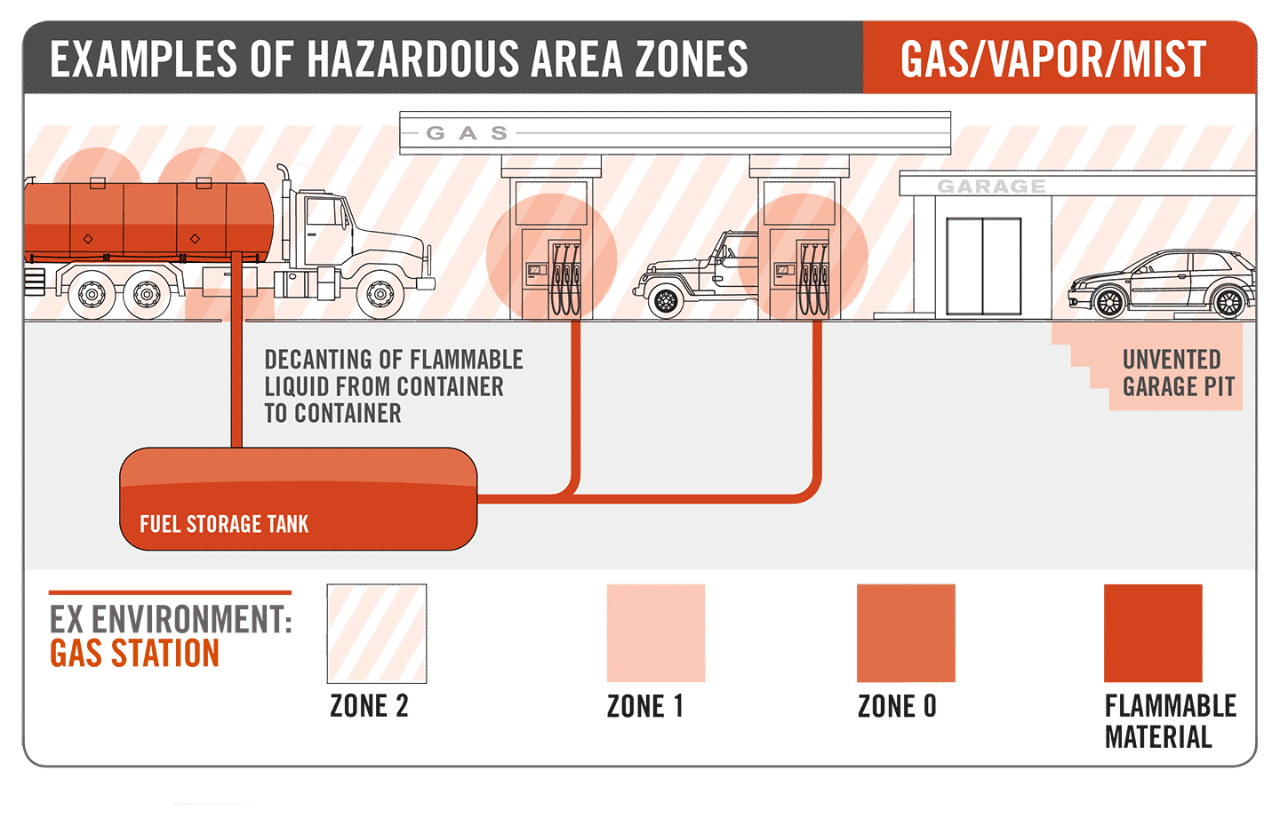

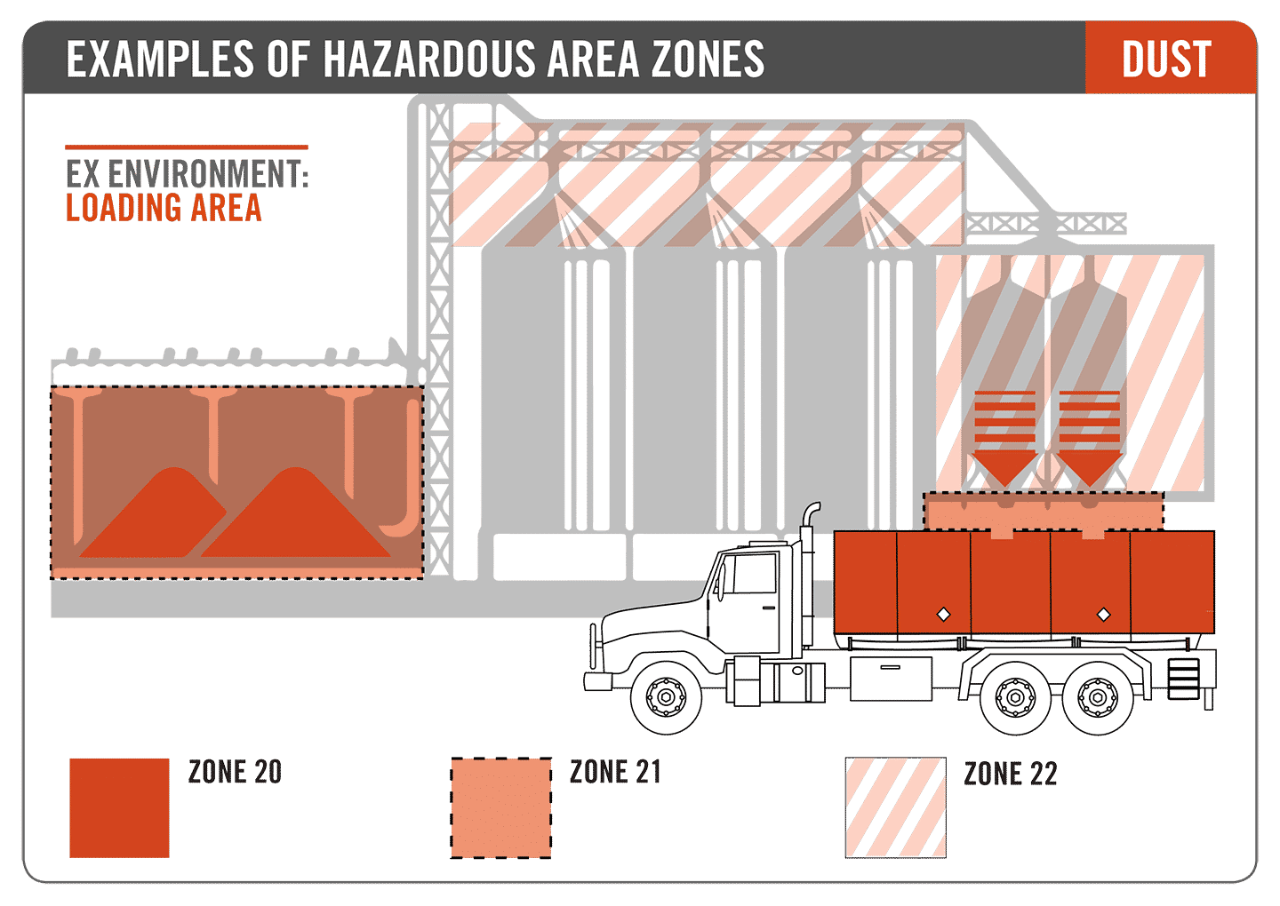

| ATEX | EU, EEA | Directive 2014/34/EU, EN 60079 series | Zone (0/1/2 gases, 20/21/22 dust) | Explosive atmospheres in Europe | ATEX Info |

| Hazardous Locations | US (OSHA, UL) | UL 121201, ANSI, NFPA 70 (National Electrical Code (NEC)) standards | Class I and Class II, Division 2; Class III, Divisions 1 and 2 | Hazardous locations in the United States | ANSI/UL, Class I, Division 2 (CID2) Info |

| IECEx | Global (IEC, >35 countries) | IEC 60079 series, harmonizing with national codes | Zone (0/1/2 gases, 20/21/22 dust) | International projects and cross-licenses | IECEx Info |

Glossary of Terms

- ANSI: American National Standards Institute, overseeing US safety standards and promoting uniformity in product testing and certification.

- UL: Underwriters Laboratories, a globally recognized Nationally Recognized Testing Laboratory (NRTL) (Nationally Recognized Testing Laboratory) for US product safety testing.

- UL 121201: The principal UL standard for nonincendive electrical equipment in hazardous US environments (Class I/Division 2).

- Class I, Division 2: Class I, Division 2-a US classification denoting areas where flammable gases/vapors are only present in abnormal conditions; not a standard but an environmental definition.

- ATEX: A suite of European Union directives governing equipment and protective systems in potentially explosive atmospheres, referencing the Zone classification system.

- IECE: International Electrotechnical Commission Explosive Atmospheres scheme, harmonizing EN/IEC standards across countries for equipment used in hazardous environments.

- Zone/Class/Division: Systems for categorizing the risk level and presence of hazardous substances; used to determine required certification for device deployment.

- Nonincendive/Explosion-Proof/Intrinsically Safe: Three distinct equipment protection strategies: nonincendive (safe in normal operation), explosion-proof (contains an internal ignition), and intrinsically safe (limits all internal energy to below ignition thresholds, even in fault conditions).

INTRODUCTION: WHY CERTIFICATION MATTERS

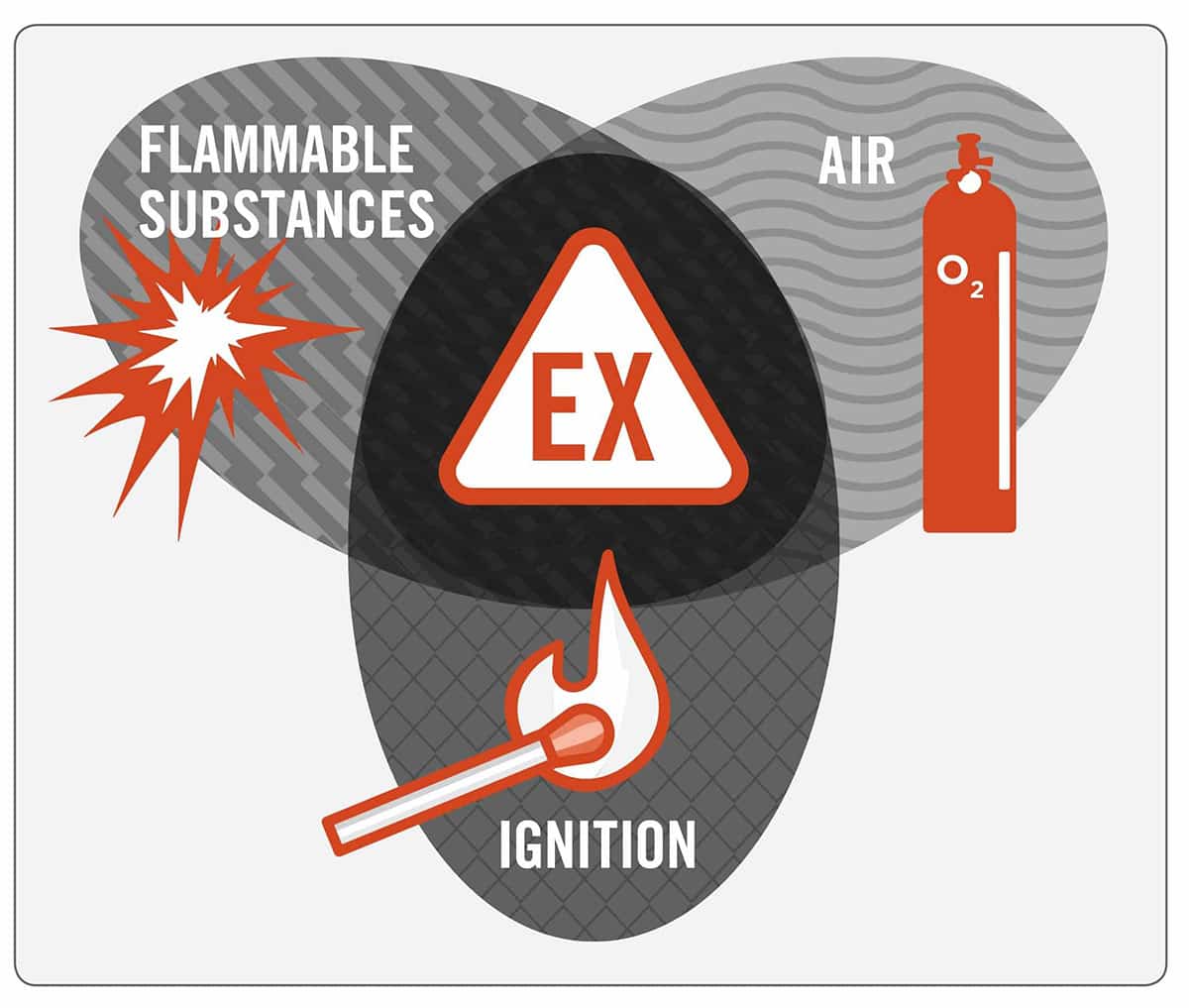

Using electronics in places with flammable gases, dust, or fibers is risky. If devices aren’t properly certified, even a small spark or too much heat can cause an explosion. That’s why certifications—like Class I, Division 2 for the US, ATEX for Europe, and IECEx for global markets—exist. They protect workers, ensure businesses stay compliant with the law, and help avoid costly accidents.

Different countries and industries rely on their own standards. A device certified in one region may not be approved in another. For anyone buying, using, or managing rugged devices in hazardous locations, it’s important to know which certifications apply to your site and why.

WHY CERTIFICATION MATTERS

Using electronics in places with flammable gases, dust, or fibers is risky. If devices aren’t properly certified, even a small spark or too much heat can cause an explosion. That’s why certifications—like Class I, Division 2 for the US, ATEX for Europe, and IECEx for global markets—exist. They protect workers, ensure businesses stay compliant with the law, and help avoid costly accidents.

Different countries and industries rely on their own standards. A device certified in one region may not be approved in another. For anyone buying, using, or managing rugged devices in hazardous locations, it’s important to know which certifications apply to your site and why.

HOW HAZARDOUS LOCATION STANDARDS DEVELOPED

How US Safety Standards Began: Class I, Division 2

ANSI/UL certification started as a practical response to real dangers in American workplaces like oil fields and chemical plants. As more factories and worksites started using electricity, there were serious accidents—sparks or heat would set off explosions if flammable gases or dust were around. To solve this, groups like Underwriters Laboratories (UL) and the National Electrical Code (NEC) created rules for what kinds of devices could be used, and where. Over time, these standards were fine-tuned to keep up with new technology and lessons learned from past incidents. Today, a UL-certified device means it’s been tested to help prevent those workplace explosions and fires, making worksites safer for everyone.

The European and International Model: ATEX & IECEx

In Europe, high-profile workplace incidents in the second half of the twentieth century prompted the creation of region-wide standards. The ATEX directives—2014/34/EU and 99/92/EC—established uniform guidelines for the certification and use of equipment in explosive atmospheres. This legal harmonization ensured that devices sold and used in any EU country met the same rigorous requirements, streamlining both commerce and cross-border safety.

Globally, the IECEx scheme was introduced by the International Electrotechnical Commission to reduce the complexity multinational firms faced when deploying gear in various countries, each with their own codes. IECEx bridges these gaps with a consistent framework that now spans over 35 nations, particularly useful for international projects (e.g., oil and gas pipelines, global mining operations).

UNDERSTANDING THE CERTIFICATION PROCESS

Class I, Division 2 Certification: Step-by-Step

Risk Assessment and Design: Manufacturers begin with a full hazard assessment, mapping which Classes, Divisions, and Groups their target device must serve.

Engineering for Nonincendive Performance: Circuits are designed to prevent arcing, surface temperatures are controlled through heat sinks or enclosures, and all switches or connectors are sealed.

Testing with an NRTL: Devices must be submitted to an approved NRTL such as UL. Several rounds of testing simulate normal and fault conditions, exposure to chemicals, vibration, dust, and temperature extremes.

Labeling and Documentation: Upon passing, the device receives a certification label (e.g., UL 121201, Class I, Division 2) and must be shipped with full test reports and instructions for ongoing compliance.

Ongoing Surveillance: UL and other NRTLs periodically audit manufacturers to ensure ongoing conformity with certification requirements even after the product has been released.

ATEX/IECEx Certification: Step-by-Step

Zone Mapping and Hazard Analysis: Companies classify facilities by Zones based on the frequency and duration of explosive hazard presence.

Design per EN/IEC Standards: Devices are engineered to meet specific protection concepts (e.g., Ex nA for non-sparking, Ex i for intrinsic safety, Ex d for explosion-proof).

Testing by Notified (ATEX) or ExCB (IECEx) Bodies: Accredited labs evaluate compliance with all applicable EN/IEC standards, including ingress protection, flameproof integrity, and temperature class.

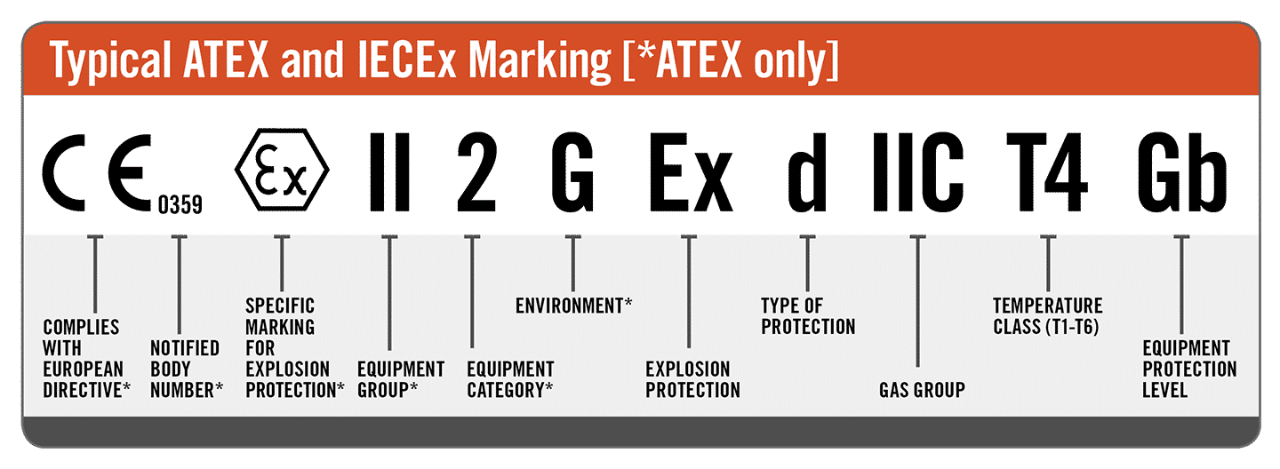

Marking and Ex Documentation: Devices receive the “Ex” label (e.g., “Ex II 3 G”) and full technical files for legal registration and auditing.

- Surveillance and Re-Certification: Ongoing monitoring, factory audits, and—in some cases—annual re-assessment protect the legal certainty of compliance.

DEEP DIVE: PROTECTION CONCEPTS

In both US and international contexts, different protection techniques are tailored for risk severity:

Nonincendive (Hazardous Locations: Class I, Division 2): Safe under normal operation; suitable for most manufacturing, utility, and logistics operations where hazard is rare.

Intrinsically Safe (IS) (Class I, Division 1; Zones 0–2 for gas and 20–22 for dust): Even in the case of faults, circuits cannot produce enough energy to ignite a hazardous mixture. Often used in upstream oil & gas, chemical reactors, underground mines.

Explosion-Proof/Flameproof (Hazardous Locations, ATEX/IECEx): Equipment is designed to contain an internal explosion without igniting the surrounding environment. Used in high-vapor or dust applications, and when routine exposure is expected.

Case Example: For a wastewater treatment facility in Texas, portable field tablets must be UL 121201 certified (nonincendive) to work safely around methane leaks (CID2). Meanwhile, a refinery in Rotterdam will deploy ATEX-certified devices (Zone 2) on the plant floor, with more stringent IS handhelds in confined, persistent hazard areas (Zone 0/1).

DETAILED INDUSTRY APPLICATIONS

Upstream (Exploration & Production): Drilling rigs in the US require Class I, Division 2-certified data acquisition devices (often with IS ratings for CID1), while rigs off the coast of Norway would demand ATEX or IECEx.

Midstream (Pipelines & Storage): Data loggers at US compressor stations must carry UL marks for Class I, Division 2, ensuring compliance with Department of Transportation regulations. For international LNG transfer terminals, dual ATEX/IECEx certification may be required.

Downstream (Refining & Distribution): Devices used within process safety areas must be chosen based on both the specific hazardous classification of each area and the regulatory authority. This approach minimizes explosion risk and helps facilities maintain insurance coverage.

Chemical and Pharmaceutical Manufacturing

Processing Vats and Reactors: Vapors from solvents necessitate strictly certified laptops/tablets—US plants require ANSI/UL (with IS for Division 1), while European facilities are bound by ATEX rules.

Quality Assurance Labs: Even low-level solvent fumes can pose hazards. Deploying equipment with the correct Zone/Division certification safeguards both operators and product quality.

Utilities and Energy Distribution

Power Generation (Gas, Hydro, Renewables): ANSI/UL is universal for US utility substations, while large, export-class facilities often operate dual-certified devices to meet the rules of regions they serve.

Electric and Gas Distribution: Ruggedized, certified tablets allow field inspectors to log data around substations, valves, and meters without introducing risk—all while maintaining OSHA compliance.

Surface/Underground Mining: Methane gas and coal dust hazards—for example, in Australia or the US—mean each location requires specific certification (UL in the US, IECEx internationally).

Agriculture & Grain Storage: Dust ignition events necessitate certified electronics around silos and conveyor lines, with appropriate Class II or Zone 21/22 ratings.

Fuel Storage/Transfer: Loading docks, depots, and vehicle fueling installations worldwide require certified tablets to comply with both local (ANSI/UL or ATEX) and international (IECEx) mandates.

Aerospace and Defense: Locations where jet fuel or munitions are present must use electronics with certifications corresponding to the risk zone and jurisdiction to support both safety and contractual obligations.

CASE STUDY: CHOOSING THE RIGHT CERTIFICATION FOR GLOBAL OPERATIONS

An international oilfield services company operates across Texas, North Dakota, the North Sea, and the Middle East. Their rugged computing solution must:

Be UL 121201 certified for US sites and meet all OSHA and insurance requirements.

Carry dual ATEX/IECEx certification to legally deploy the same assets and workflows on North Sea platforms and desert refineries.

Use a unified device platform (e.g., Getac F110, K120) to minimize training costs and reduce device management complexity.

Reference clear product documentation and global support for uninterrupted operations—even as teams move across regulatory boundaries.

Such multi-certified deployments enable firms to streamline inventory, protect workers, and simplify compliance, with auditable certification files supporting reviews by regulators and insurance auditors in any country.

THE FUTURE: TRENDS, INNOVATION, AND AI IN CERTIFICATION

Evolving Regulatory Requirements

As industries digitize and processes become increasingly automated, the scope and complexity of safety standards continue to evolve. IoT sensors, cloud-driven analytics, and edge computing—often installed in hazardous areas—must now meet certification requirements that keep pace with advancing technologies.

Regulatory authorities in the US and globally are collaborating to harmonize certain standards, yet differences will persist due to local laws, historical practices, and unique regional risks. Getac continually invests in recertification and cross-standard compliance to ensure customers in every market can adopt advanced technologies without risking non-compliance or safety failures.

REGULATORY, LEGAL, AND INSURANCE IMPLICATIONS

Legal Mandates

In the United States, OSHA mandates that all electrical devices in classified areas must be certified by an NRTL (like UL or Intertek). The failure to use correctly certified equipment can result in legal action, site shutdowns, and severe financial penalties.

Within the EU, ATEX is codified in law, with non-compliance potentially leading to product bans, workplace fines, or criminal prosecution. IECEx is not always mandatory but is increasingly recognized by regulatory authorities in Asia, the Middle East, and Africa.

Insurance Requirements

Insurance policies in all regions increasingly require proof of certification for assets deployed in hazardous environments. Claims can be denied if incidents occur and equipment is found to be uncertified or incorrectly specified. Having auditable certification documents and a clear deployment strategy is vital for risk mitigation.

GLOBAL SUPPLY CHAIN AND PROCUREMENT CONSIDERATIONS

Multinational companies face added complexity as they must ensure their purchased equipment can be legally used in every region of operation. Dual- or triple-certified rugged devices allow simpler global procurement, reducing the risk of expensive retrofits, shipment delays, or customs issues.

When seeking certification, organizations should:

Audit operational areas and map each to its risk classification (US Class/Division/Group or EU/IECEx Zone).

Document certification requirements in procurement contracts.

Request full technical and certification files from vendors.

Plan for periodic audits and re-certification, especially when updating devices or accessories.

GETAC ATEX, IECEx, ANSI/UL CERTIFIED RUGGED DEVICES

Working in hazardous areas requires equipment rugged enough to withstand extreme situations while simultaneously minimizing risks to the safety of your team. Getac is proud to offer a range of tablets that meet the stringent regulations to work in explosive environments and is ATEX and IECEx (for details please check the specific product's spec sheet) certified.

FAQ: Expanding Common Certification Concerns

How often do standards or certification requirements change?

Standards bodies update requirements frequently, sometimes annually, as new accident data or technologies emerge. Staying abreast of these changes is critical. Many top manufacturers provide notifications and updated documentation as standards evolve.

What documentation should I keep on file for compliance?

Always retain the certificate of conformity, latest NRTL or Notified Body reports, and a copy of the technical construction file provided by the vendor. This documentation may be requested during inspections or insurance audits.

Are repairs or modifications allowed on certified devices?

Repairs must be performed by the manufacturer or a certified service provider using approved spare parts. Unapproved changes or third-party modifications can void certification.

How do I verify a device's certification?

Every device should have a certification label specifying the applicable standard and risk classification (e.g., UL mark and Class I Division 2, or Ex II 3 G for ATEX). Always cross-reference with the vendor's online certification verification tool or request documentation.

Can I use consumer devices with ruggedized cases as substitutes?

No. While ruggedized consumer devices can survive harsh conditions, without proper certification they are not compliant for use in hazardous or classified locations.

KEY TAKEAWAYS

Certification is required for legal operation and safety in hazardous environments—choose according to geography, risk level, and business requirements.

ANSI/UL applies to the US using the Class/Division/Group system; ATEX (EU) and IECEx (global) use a Zone-based approach.

Dual/triple-certified devices from suppliers like Getac equip organizations for regulatory flexibility and safe operations worldwide.

Staying current with certification updates, maintaining documentation, and rigorous monitoring support compliance—and build trust with regulators and global partners.

For detailed, project-specific advice, or to request certification packs and pricing for US and international deployments, contact the Getac solutions team.