-

SOLUTIONS

-

-

-

Getac Select ®

A combination of rugged computing devices, software, accessories and professional services in a purposeful range of specifically tailored solutions.

-

Getac Video Solutions

Video capture, evidence management, rugged hardware and robust software solutions for law enforcement and other industries.

-

-

-

-

PRODUCTS

-

INDUSTRIES

-

-

-

Defense

Mission-critical COTS computing that delivers high powered processing and reliability in operational environments

-

Public Safety

Law Enforcement, EMS, Fire & Rescue applications

-

Utilities

Smart Meter Reading and Installation, On-site Safety, Utility Asset Management, Workforce Management for Utilities, Mobile GIS, Surveying and Mapping

-

Transportation & Logistics

Railroad Management, Airport Management, Port Management, Long-haul Delivery Fleet Management, Warehouse Materials Handling

-

Industrial Manufacturing

Industrial Programming and Robotic Control, Facility management, Compliance and Inspections, Workforce Management, Inventory and Warehouse Management, Factory Automation and Plant Monitoring, EAM and CMMS Solutions.

-

Automotive

Optimized Rugged Mobile Solutions to drive a smarter approach throughout the automotive value-chain.

-

Natural Resources

Mining, Forestry and Construction applications

-

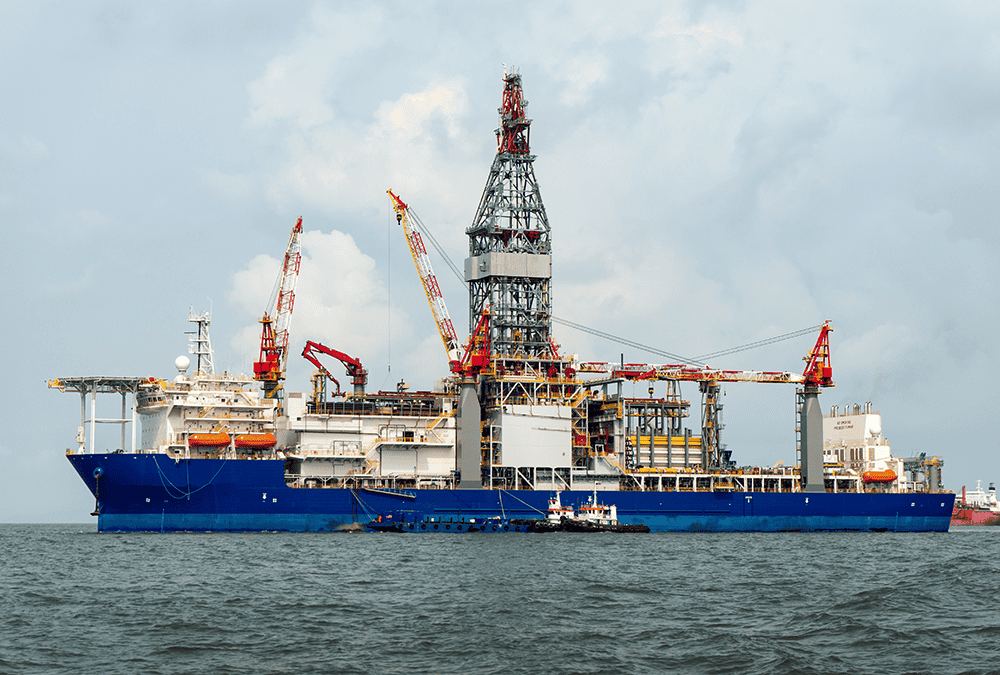

Oil & Gas

Remote Support, Asset Management, Field Data Analysis, Workplace Safety

-

- Explore all industries

-

-

-

COMPANY

-

HELP & SUPPORT

- |

-

- Americas

-

Europe

-

-

- Hungary (English)

- Ireland (English)

- Italy (Italiano)

- Kazakhstan (Русский)

- Kyrgyzstan (Русский)

- Latvia (English)

- Lithuania (English)

- Mongolia (English)

- Netherlands (English)

- Netherlands (Nederlands)

- Norway (English)

- Poland (English)

- Poland (Polski)

- Portugal (English)

- Portugal (Português)

- Romania (English)

-

- Asia Pacific

- Middle East & Africa